TLDR;

This video discusses Rolls-Royce's strategic shift back into the single-aisle aircraft engine market with its UltraFan technology. It covers the company's past struggles, its financial recovery, the UltraFan engine's design and capabilities, potential aircraft applications, and the challenges Rolls-Royce faces in competing with existing engine manufacturers.

- Rolls-Royce is re-entering the single-aisle aircraft engine market after exiting in 2011.

- The UltraFan engine features a geared fan design for improved efficiency and reduced weight.

- Rolls-Royce aims to test a smaller UltraFan prototype by 2028, targeting next-generation single-aisle aircraft.

- Potential applications include replacements for the Boeing 737 and Airbus A320, as well as military aircraft like the C-17 and blended wing-body concepts.

- Rolls-Royce faces challenges in production volume, reliability, and competition with Pratt & Whitney and CFM.

Why did Rolls-Royce leave the Single-Aisle Market? [0:30]

Rolls-Royce has experienced financial difficulties and engine-related issues in recent years, particularly with the Trent 7000 engines for the Airbus A330 and the Trent XWB engines for the Airbus A350-1000. The company is addressing these issues while also developing the UltraFan engine as a replacement for the Trent family. The UltraFan features a large fan disk and a geared fan design to improve efficiency. Rolls-Royce's last engine for single-aisle airliners was the RB-211, used in the Boeing 757. In 2011, Rolls-Royce exited the single-aisle market by selling its stake in the International Aero Engines Consortium to Pratt & Whitney for $1.5 billion, focusing on the long-haul market.

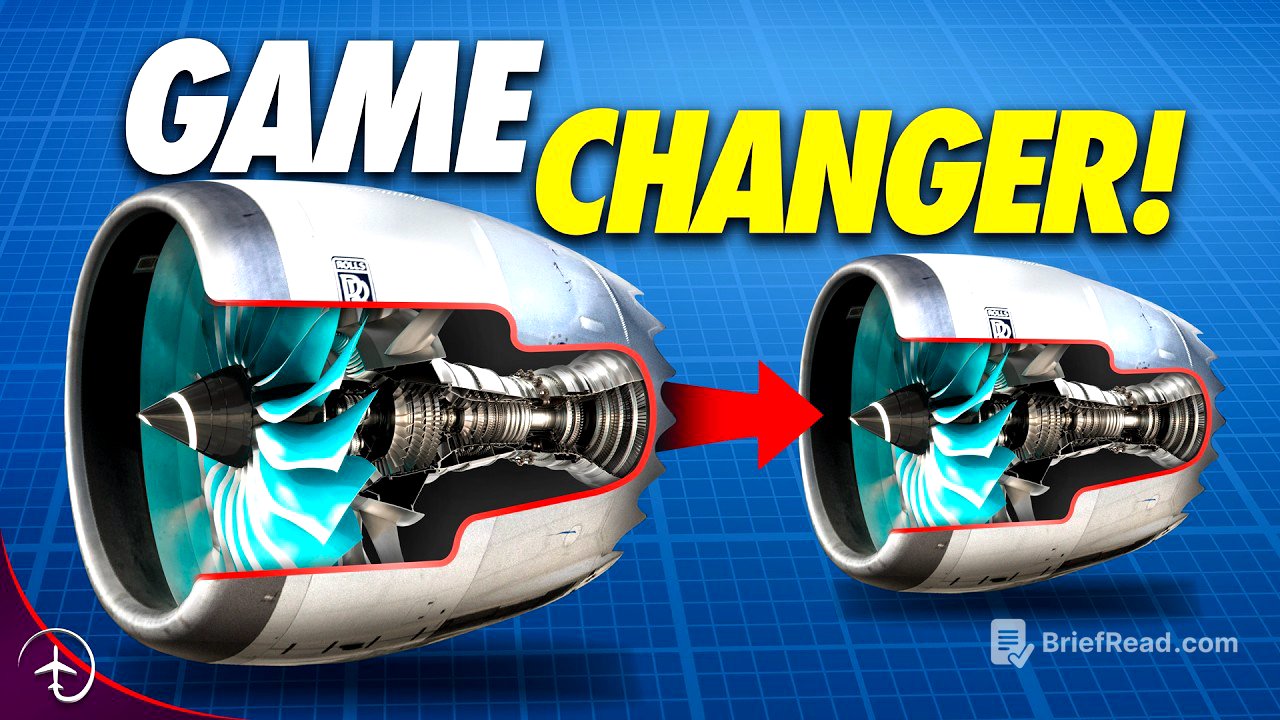

What Is the Rolls-Royce Ultrafan Engine? [3:20]

The Rolls-Royce UltraFan engine is equipped with a geared fan, allowing the fan blades to spin slower and improving efficiency. This design simplifies the rest of the engine, reducing complexity and weight. The geared fan technology dates back decades but is now viable for large widebody engines due to advancements in gearbox strength. The UltraFan's design saves weight overall by allowing engine makers to speed up other sections of the engine, such as the compressor and turbine stages. Slower fan blade speeds also reduce the energy of each blade, requiring less sturdy casing and further weight reduction.

Rolls-Royce Financial Recovery [8:15]

Rolls-Royce's focus on the long-haul market became problematic during the COVID-19 pandemic, as international travel suffered significantly. The grounding of wide-body aircraft led to a sharp decline in service revenues, causing the company to lose billions. However, Rolls-Royce has since staged a recovery due to the resurgence of long-haul travel and internal reorganization efforts. In 2023, the company reported a record free cash flow and operating profits, enabling them to fund research and development projects, including the UltraFan. Rolls-Royce is now exploring new markets, including the narrowbody sector, leading to the development of a smaller UltraFan demonstrator.

Which Planes Could Use the Ultrafan Engine? [10:55]

Rolls-Royce is finalizing the design of a smaller UltraFan demonstrator, producing around 30,000 pounds of thrust, suitable for replacing engines on aircraft like the Airbus A320 and Boeing 737 families. The company aims to begin testing this prototype in 2028, aligning with the timeline for potential next-generation single-aisle aircraft. Building an UltraFan for single-aisle aircraft presents unique challenges, including miniaturizing the engine core while maintaining a high bypass ratio. Rolls-Royce will need to combine its work on the UltraFan with technologies from its Pearl family of corporate jet engines, which utilize advanced high-temperature materials. Potential applications for the UltraFan include replacements for the Boeing 737 and 757, as well as military aircraft like the C-17 and blended wing-body concepts.

Can Rolls-Royce Compete? [17:30]

Rolls-Royce faces challenges in re-entering the single-aisle market, including competition with the existing duopoly of Pratt & Whitney and CFM. Producing engines for single-aisle aircraft requires higher production rates and ensuring reliability and durability for high-cycle use. Rolls-Royce needs to convince aircraft manufacturers, airlines, and suppliers that it can meet these demands. The company is reportedly seeking government funding assistance for the project, estimated to cost around $3.9 billion. Rolls-Royce could focus on a mid-size engine for projects like the JetZero blended wing-body concept or aim for the heart of the market by targeting replacements for the Boeing 737 and Airbus A320.