TLDR;

Alright, so this talk, "The Good, the Bad, and the Ugly," is all about designing and building aluminium high-speed vessels. The speaker emphasizes that just following class rules isn't enough; good design needs a solid understanding of structural implications. Fabrication quality is super important, and fatigue is a major concern with aluminium. Ultimately, quality—in design, fabrication, and execution—is what makes or breaks these vessels.

- Class rules are minimum standards, not gold standards.

- Naval architects are responsible for design, not classification societies.

- Quality is everyone's responsibility in the shipyard, not just the surveyor's.

Introduction [0:03]

The speaker kicks off by explaining the title, drawing a parallel between the high-speed vessel industry and a spaghetti western, complete with good, bad, and ugly elements. He questions what makes a design or fabrication "good" and stresses the importance of quality in the mix.

Design Considerations [3:20]

The speaker points out that designing to class rules only meets the minimum standards and doesn't guarantee fitness for purpose or longevity. Class rules don't cover all design issues, and it's the naval architect's job to understand the structural implications. He gives examples of how strictly adhering to class rules can lead to peculiar structural shapes with major changes in stiffness, which aren't addressed by the rules.

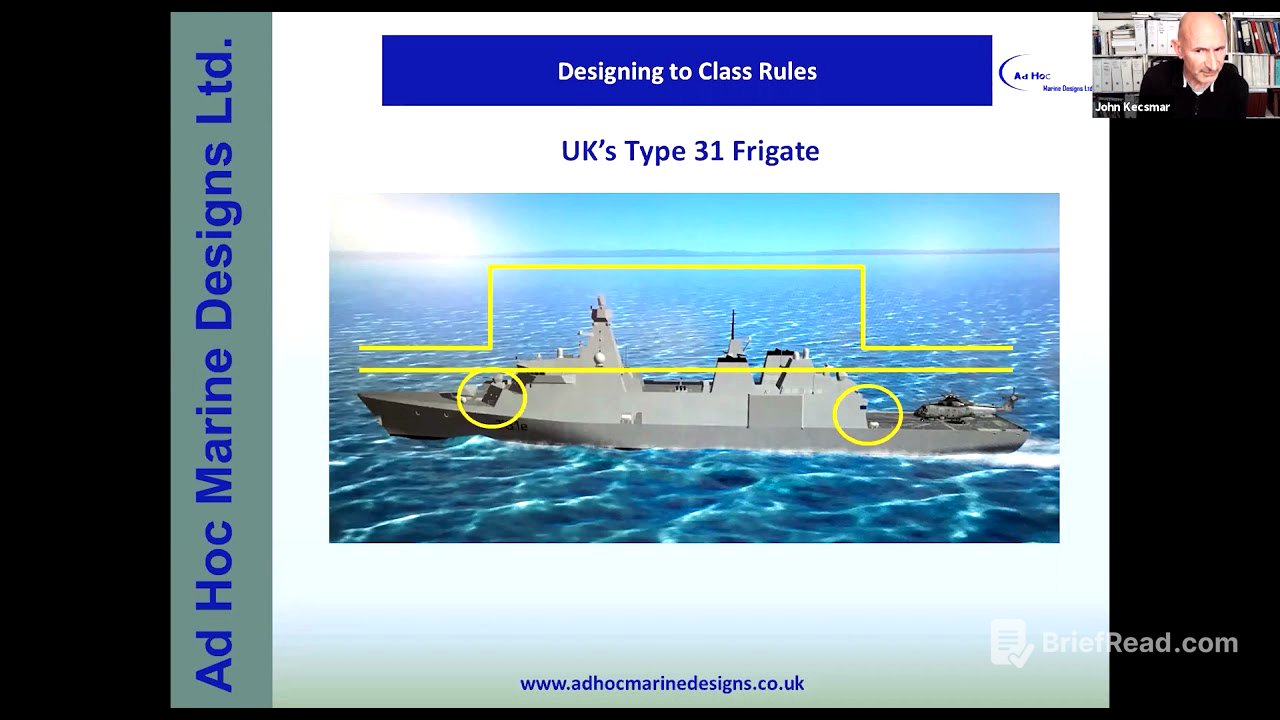

Importance of Structural Understanding [6:01]

The speaker shares examples of design reviews where he found issues like slender side frames connected to very stiff sections, causing problems. He uses the Type 31 frigate as an example of how changes in stiffness along the hull length can lead to stress concentrations. He illustrates how to properly distribute concentrated loads, like those from lifting lugs, by gradually transitioning plate thicknesses.

Design Choices and Their Impact [8:13]

The speaker talks about using FEA to identify areas needing attention in detailing frames. He compares straight-line and curvy frame designs, noting the production benefits of straight lines versus the aesthetic appeal of curves. Citing Japanese research from the 1980s, he shows how frame shape affects stress concentration, with significant differences in stress factors between different connection types.

Welding and Material Properties [10:33]

The speaker discusses how the choice of stiffening shapes affects weld quality, noting that the angle bar makes it difficult for welders to achieve a good weld on the inner face. He analyzes a T-bar connection, explaining how a weld intended for shear can experience biaxial stress due to tensile loads in the flange. He emphasizes the importance of understanding material tempers, particularly 5083 aluminium, and how different tempers (O temper vs. H321) affect overload capacity and bend radius.

Fabrication and Temper Considerations [12:32]

The speaker explains how the temper of aluminium affects its ability to withstand bending and forming. He notes that exceeding the minimum bend radius can work-harden the alloy, reducing ductility and increasing the risk of failure. He highlights the implications for fabricating structures like water jet ducts, where multiple small radii require careful attention and the use of O temper.

Defining Quality [16:02]

The speaker uses the example of a Skoda car to illustrate the concept of quality, showing how a terrible car can still be roadworthy and legal. He then shows the same car 20 years later, looking much better, to emphasize that quality is more than just meeting the bare minimum. He introduces Maslow's hierarchy of needs to explain motivation and satisfaction in relation to quality.

Quality Control vs. Quality Assurance [17:37]

The speaker breaks down quality into quality control (detecting) and quality assurance (preventing). He questions whether quality control is a form of motivation and discusses the philosophical aspects of quality assurance in relation to shipyard training and motivation. He criticizes shipyards that rely solely on class inspections as a quality system, calling it reactive rather than proactive.

Limitations of Class Inspections [19:05]

The speaker points out that class inspections, like those from DNV, only visually and radiographically examine a small percentage of welds (2-5%), leaving the vast majority untested. He notes that most ship structures consist of fillet welds, which can't be x-rayed, relying on visual examination and dye penetrant testing.

Examples of Poor Weld Quality [19:59]

The speaker shares results from his PhD experiments, showing examples of poor weld quality, including lack of fusion, failure to grind off dirt and oxide layers, and improper butting of rider bars. He shows x-rays of unacceptable welds and highlights issues like excessive stop-starts, lack of fusion, and oversized fillets, all of which were passed by class.

The Elephant in the Room: Fatigue [23:21]

The speaker identifies fatigue as a major cause of failure, resulting from a chain of events. He notes that aluminium lacks an endurance limit, meaning it will eventually fail with enough flexing. He presents research showing a significant reduction in allowable stress for aluminium in seawater environments, leading him to design waterjet ducts to a very low stress limit.

Improving Fatigue Life [25:14]

The speaker describes using FEA to design waterjet ducts with low stress values. He details the use of J-preps, heli-shield gas, and 5356 wire to improve weld quality. He also mentions undercutting the toe of the weld to improve fatigue life, based on research findings.

Strain Hardening and Crack Initiation [27:44]

The speaker explains how strain hardening, used to improve mechanical strength, involves the same slip planes used in crack initiation. He warns that even small score marks can act as dislocations, leading to crack growth. He describes the stages of crack growth, from initiation to failure.

Welding Practices and Fatigue [30:09]

The speaker points out that larger weld beads reduce fatigue strength due to localized stiffness. He notes that misalignment of plates and angular misalignment can significantly increase stress concentration factors. He describes how he changed production procedures to ensure strict quality control and address non-conformities.

The Payoff of Quality Control [32:19]

The speaker shares the success story of the Hong Kong Tri-Cats, 45-meter vessels that have been running for over 25 years without structural failures. He contrasts this with another shipyard that built a waterjet duct with poor quality welds, leading to failure within weeks of service.

Fatigue Analysis Methods [34:27]

The speaker mentions fatigue analysis methods from the International Institute of Welding (IIW), including nominal stress, hot spot stress, and notch stress approaches. However, he finds these methods a bit abstract and warns against treating the calculated values as the be-all and end-all. He cites a paper showing a wide range of fatigue life predictions for the same joint using different methods.

Improving Stress Distribution [36:41]

The speaker presents an FEA analysis showing how changing the shape of a mouse hole can significantly reduce stress concentration in a welded joint, potentially doubling fatigue life. He describes designing Lockheed Martin's swath slice vessel, using IIW fatigue categories to guide design stress values and specifying heli-shield gas and joint detailing.

Attention to Detail and Examples of Poor Fabrication [40:51]

The speaker emphasizes the importance of attention to detail and inspecting welds on the shop floor. He shows examples of poor fabrication, including sword cuts, lack of weld around mouse holes, cold and blobby welds, and distorted structures corrected with heat (which is a no-no for aluminium).

Conclusion: Quality is Key [43:55]

The speaker concludes that quality is the real glue holding the entire process together. It's the responsibility of everyone in the shipyard, not just the surveyor or class. He shows examples of good and poor quality fabrication, emphasizing that good quality is visually apparent and doesn't require expertise to recognize.