TLDR;

This video provides a comprehensive guide to understanding the anatomy of screws and how to choose the right one for woodworking projects. It covers the four basic parts of a screw (tip, thread, shank, and head), discusses different types of screw tips and threads for various wood types, and explains the importance of pilot holes and clearance holes to prevent splitting and jacking. The video also touches on different screw head shapes, drive types, and common screw types used in woodworking, offering practical tips and golden rules for selecting the appropriate screw for the job.

- Understanding the four basic parts of a screw: tip, thread, shank, and head.

- Matching screw threads to wood type: coarse threads for softwoods, fine threads for hardwoods.

- Preventing wood splitting and jacking through proper techniques like pre-drilling and using partially threaded screws.

- Choosing the right screw head and drive type for optimal performance and ease of use.

Intro [0:00]

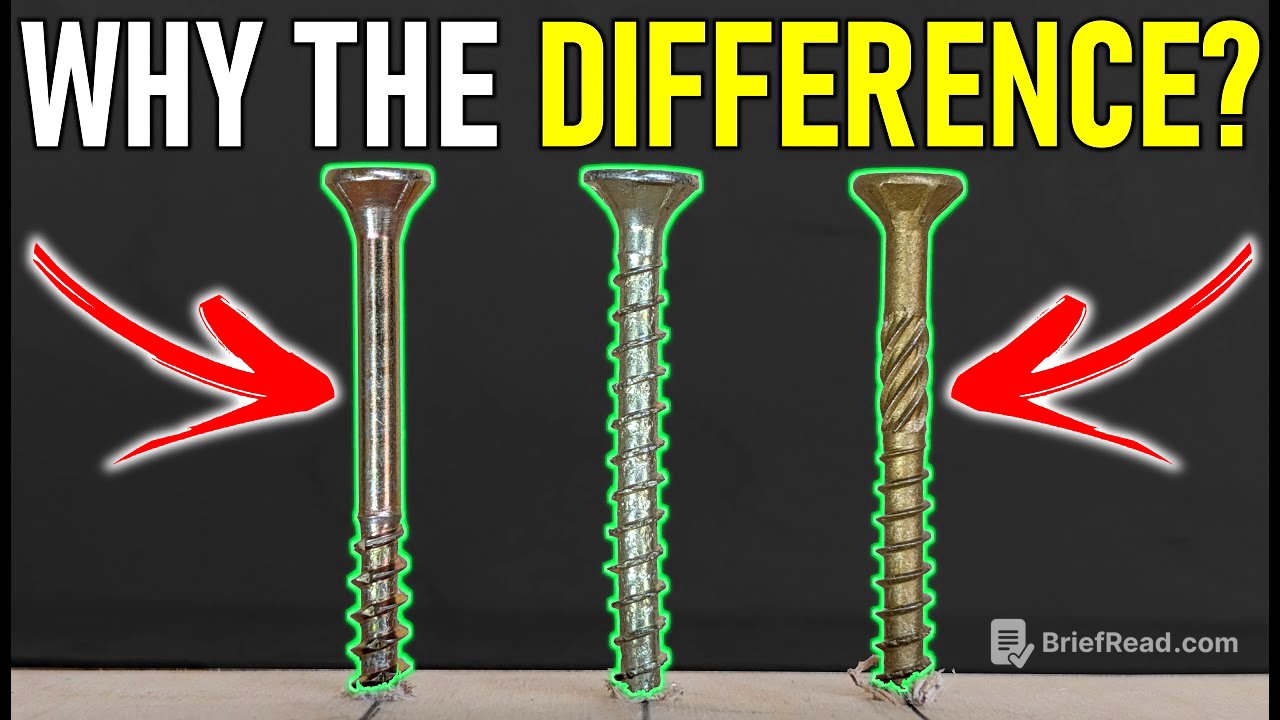

The video introduces the idea that not all screws are the same and poses several questions about why different screws behave differently in various situations. It highlights the importance of understanding the components of a screw before selecting the right one for a project. The video promises to answer these questions by exploring the different parts of a screw and their functions.

The Tip [0:30]

This section focuses on the screw tip and its impact on wood splitting. It explains that normal screw tips can cause cracks, especially in the "high-risk split zone," which is more prominent in hardwoods than softwoods. Special tips, like self-drilling tips with slits or serrated designs, are engineered to cut wood fibers and reduce the need for pre-drilling. However, pre-drilling is still recommended for dense hardwoods to avoid splitting. The first golden rule is introduced: when in doubt, drill a pilot hole, especially with expensive wood or critical joints.

The Threads [2:05]

The discussion shifts to screw threads, emphasizing the classic woodworking rule of matching the thread to the wood. Coarse threads are suited for softwoods like pine and plywood because they grip the spongy fibers effectively. Fine threads are better for hardwoods like oak and maple, slicing neatly into the dense fibers. The video notes that fine-threaded wood screws are hard to find outside of those used for drywall or metal, and often still require pre-drilling. Advanced coarse-threaded screws with special cutting tips have been developed to prevent splitting, but the presenter still advocates for pilot holes for guaranteed results. The second golden rule is: don't just rely on technology, develop good skills.

The Shank [5:02]

This part explains the function of the screw's shank, differentiating between fully threaded and partially threaded screws. Fully threaded screws provide great holding power but can cause "jacking" (boards being forced apart) if there's a gap between the boards. Partially threaded screws have a smooth, unthreaded shank that glides through the top board, allowing the threads to bite only into the second board and pull the joint tight. Ribs under the head of some screws widen the screw hole to prevent binding and minimize wood splitting. Pre-drilling with pilot and clearance holes is presented as a foolproof method to prevent jacking. The third golden rule: If you need to pull a joint tight, choose the screw with the mullet (partially threaded).

The Head [8:29]

The head's two main jobs are to stop the screw and provide a way to drive it. The video focuses on two main head shapes: flatheads (for a flush finish) and metal hat family heads (like truss heads, for attaching hardware). Achieving a professional look with flatheads requires either using a countersink bit or screws with fiber-shredding ribs under the head. The section also covers different drive patterns: slotted (the worst), Phillips (prone to camming out), square/Robertson (Canadian favorite that rarely cams out), and star drive (the best, refuses to cam out). The fourth golden rule: Choose the drive with the grip, not the one that slips.

Screw Types [10:57]

This section provides an overview of common screw types for woodworking, including construction screws (heavy-duty, all-purpose), traditional wood screws (often with soft metal and Phillips heads), cabinet screws (wider head for holding power), trim screws (small heads, some with reverse threads), and drywall screws (controversial due to brittleness). The presenter uses drywall screws only for simple shop jigs with zero weight. For his shop, he mainly uses a star drive, partially threaded number eight construction screw. The video also explains screw gauge (thickness) and length, advising to use a screw that penetrates at least 2/3 of the way into the bottom board.