TLDR;

This video presents a series of fatal accidents that occurred in shipyards, highlighting the importance of safety measures and adherence to OSHA regulations. Each scenario is analyzed to identify the contributing factors and provide recommendations for preventing similar incidents. The key takeaways include the necessity of proper training, hazard assessment, use of appropriate safety equipment, and adherence to safety protocols.

- Proper training and hazard assessment are crucial for preventing accidents.

- The use of appropriate safety equipment, such as personal flotation devices, harnesses, and non-conductive tag lines, is essential.

- Adherence to safety protocols, including lockout/tagout procedures and confined space entry requirements, is vital.

Introduction [0:01]

The video is about to show fatal accidents in shipyards. All identifying references have been removed to protect privacy interests. The depictions may be disturbing and deal with graphic subject matter.

Crane Accident 1: Crushing Incident [0:42]

Two men were unloading steel beams from a trailer using a truck-mounted crane. After unloading, the crane operator began stowing the crane, and the rigger's helper was crushed between the crane cab and the outrigger. The swing radius of the crane was not barricaded, and the crane operator did not maintain visual contact with his helpers. An audible signal should be installed on the crane to warn employees of the crane's movement.

Crane Accident 2: Untrained Operator and Equipment Failure [2:13]

A 45-ton hydraulic telescoping crane was used to move heavy loads. The crane operator had no training on this specific model and disabled the anti-two block system. During operation, the auxiliary line came under increased tension and struck and killed the rigger. The crane operator used equipment that he was not trained to operate, and safety devices were disabled. Personnel must never work under the boom hook or loads. Workers near the water's edge must wear personal flotation devices (PFDs).

Confined Space Accident 1: Flash Fire [4:30]

Two night shift employees were setting up equipment inside a barge for a painting operation. Flammable paint vapors ignited, causing a flash fire that killed both employees. There was no ventilation, the lighting equipment was not explosion-proof, and there was no air monitoring. Sufficient ventilation would have kept the concentration of flammable vapors below 10% of the lower explosive limit. A shipyard competent person should have inspected and tested the confined space. Explosion-proof lighting and equipment must be used when spraying flammable liquids.

Confined Space Accident 2: Oxygen-Enriched Fire [6:42]

Employees were cleaning a confined space using solvents. A worker used an oxygen hose to ventilate the space for 3 hours. A second shift worker entered the space smoking a cigarette, which ignited in the oxygen-enriched atmosphere, causing a fatal fire. Never use oxygen to ventilate any space; use a blower or ventilation fan. The confined space was not inspected and tested for air quality and flammability.

Fall Accident 1: Slippery Conditions [8:28]

A welder and his helper were installing guard rails on a dock from a smaller barge. The helper slipped on the icy deck and fell into the water and drowned. There were no training programs in place to prevent falling accidents, and no life rings were available. Life rings with at least 90 ft of rope attached must be available. Workers on barges must wear PFDs or tie off to a secure structure.

Fall Accident 2: Scaffold Collapse [10:23]

A welder was erecting scaffolding inside a vessel. The welder attached the scaffolding to the bulkhead using bracket clips that were temporarily tack welded in place. One of the bracket clips failed, causing him to fall 18 ft to the deck below and die. The bracket clips required full welds but were only tack welded. The welder was wearing a body harness but did not tie off. Always wear a full body harness and tie off at heights of 5 ft or more.

Equipment Modification Accident: Grinder Explosion [12:00]

A mechanic modified an electric buffing wheel into a grinder. The grinding wheel shattered, striking the mechanic with tremendous force and killing him. Equipment must never be modified for use other than its intended purpose. Ensure that the grinding wheel is appropriate for the RPM rating of the motor spindle and ring test the wheel before it is installed. A grinder must have a guard with a properly adjusted work rest and tongue guard.

Electrocution Accident 1: Welding in Water [13:41]

A welder was tasked to repair a hole in the hull of a barge. The compartment was flooded with 5 inches of water. He completed the circuit between the electrode holder and ground, and current flowed through his wet body, electrocuting him. A competent person should check the space prior to entry, and the water should have been pumped out. Do not weld while standing in water.

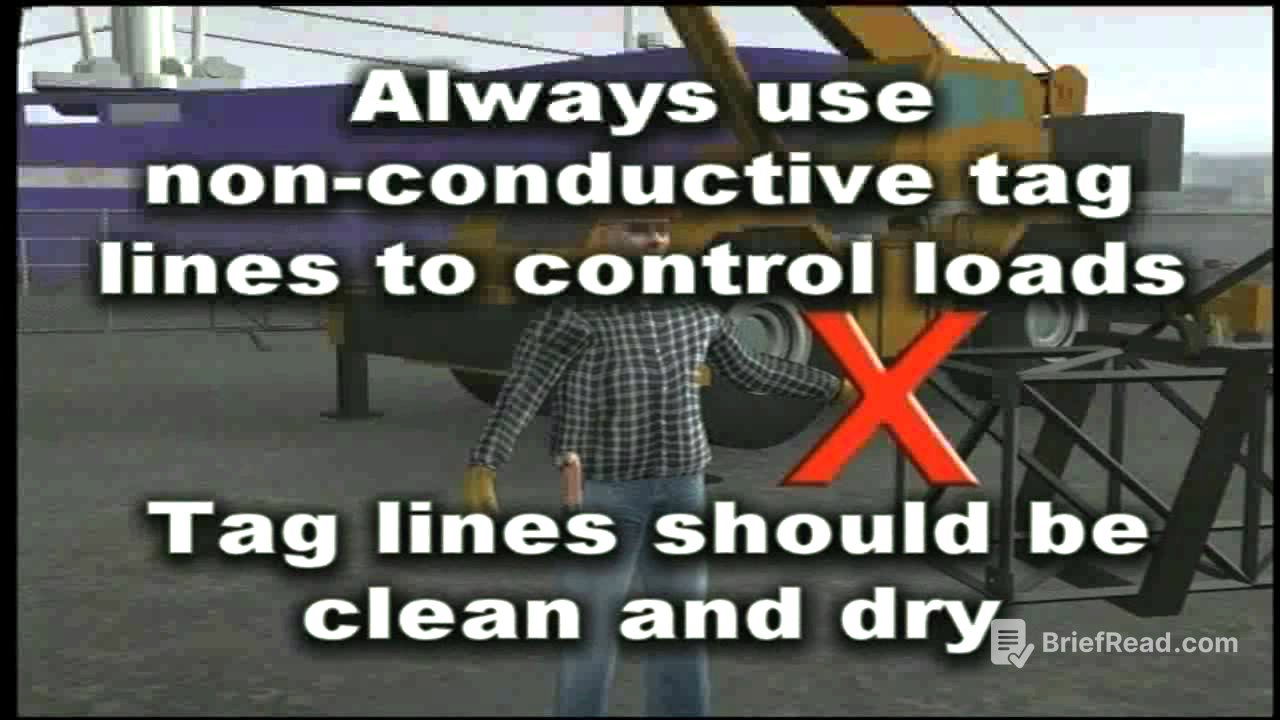

Electrocution Accident 2: Crane Contact with Power Lines [18:05]

A crane operator and two riggers were moving structural sections of a crane boom. The crane boom contacted overhead power lines, and 7,200 volts passed through the wire rope to the rigger, killing him. A safe route was not established before the crane was moved. Equipment must not be operated within 10 ft of an energized power line. Always use non-conductive tag lines to control loads.

Crushing Accident: Falling Shell Plate [20:54]

A truck crane was lifting steel shell plates. The crane operator inadvertently left the auxiliary hoist line partially extended. As the crane swung, the auxiliary line struck the top of a shell plate, causing it to fall onto the welder working below, crushing him to death. Crane operators should assess and recognize potential hazards before starting work. Unused slings and lines must be secured prior to moving the load. Crane operators must never swing loads over employees.

Struck-By Accident: Snapped Mooring Line [23:34]

Two men were rigging a chain fall to lift a mooring chain. The sling assembly was secured with a manila rope stopper, which snapped, causing the weight of the chain to be transferred back to the sling assembly. The slack assembly struck the rigger in the neck, killing him. A hazard assessment was not performed before the work began, and riggers were not properly trained. Never enter the bite of the line.

Fall Accident 3: Unguarded Catwalk [26:44]

Workers were positioned on unguarded catwalks while a crane was loading equipment onto a ship. The load disengaged from the hook and struck the catwalk, causing a worker to fall into the hopper and drown. The valve was not properly rigged to the hook of the crane. Employees working on elevated catwalks must have adequate fall protection.

Diving Accident: Lack of Safety Measures [28:42]

A dive team was installing j-bolt patches on a crude oil tank barge. A diver re-entered the water alone without a safety line and was later found unconscious and could not be resuscitated. Scuba divers must always be tied to a safety line and line tended from the surface or accompanied by another diver with continuous visual contact. A standby diver must be ready to provide assistance.

Confined Space Accident 3: Carbon Monoxide Poisoning [32:15]

Two workers were pumping out the bow compartment of a barge using a gasoline-powered pump inside the compartment. Exhaust gases from the pump built up, causing carbon monoxide poisoning, and the workers died. Confined spaces must be visually inspected and tested by a competent person. Ventilation must be provided to maintain the oxygen level and keep carbon monoxide below hazardous levels.

Electrocution Accident 3: Cross-Wired Breaker [34:42]

An electrician was working on an open electrical panel. He contacted the panel's main bus bars and was electrocuted. The tagged-out isolation breaker had been cross-wired with another breaker. Employees should verify the location of all energy isolation points and check electrical panels to ensure they are deenergized.

Steam Release Accident: Inaccurate Drawings [36:32]

A shipyard worker was preparing to replace a high-pressure steam valve. A burst of steam was released, knocking the worker to the ground and producing third-degree burns, leading to his death. Errors and omissions on the ship's as-built drawings had prevented complete isolation and draining of the steam system. Use a thermal gun to check the temperature and verify that the steam system is drained.

Conclusion [39:13]

The video urges viewers to think about the accidents and use the information to make their jobs safer. All Shipyard workers must wear or use equipment necessary to protect them from occupational safety and health hazards. If asked to perform an unsafe task, ask your supervisor or employer for help or contact your local OSHA Office.

![AP Human Geography Unit 7 Live Review! [Industrial and Economic Development Patterns and Processes]](https://wm-img.halpindev.com/p-briefread_c-10_b-10/urlb/aHR0cDovL2ltZy55b3V0dWJlLmNvbS92aS83cFF1MW42WElHOC9ocWRlZmF1bHQuanBn.jpg)