TLDR;

This video provides a high-level overview of the four most common types of welding: stick welding (SMAW), flux core arc welding (FCAW), MIG welding (GMAW), and TIG welding (GTAW). It discusses how each process works, their advantages and disadvantages, typical applications, and equipment considerations.

- Stick welding is inexpensive and portable, good for thick materials and repairs.

- Flux core welding is easier to learn than stick welding and suitable for various thicknesses.

- MIG welding is fast and clean, ideal for thin sheet metal and auto body work, but more expensive.

- TIG welding offers the most control and precision, best for aluminium, but is the most challenging to learn.

Intro [0:00]

The video introduces the four most common types of welding and explains that the video will break down each type from a high level. The presenter mentions that there are separate videos available with step-by-step instructions for each welding type, linked in the description. The current video will focus on the applications and basic functionality of each welding method.

Stick Welding (Shielded Metal Arc Welding - SMAW) [0:40]

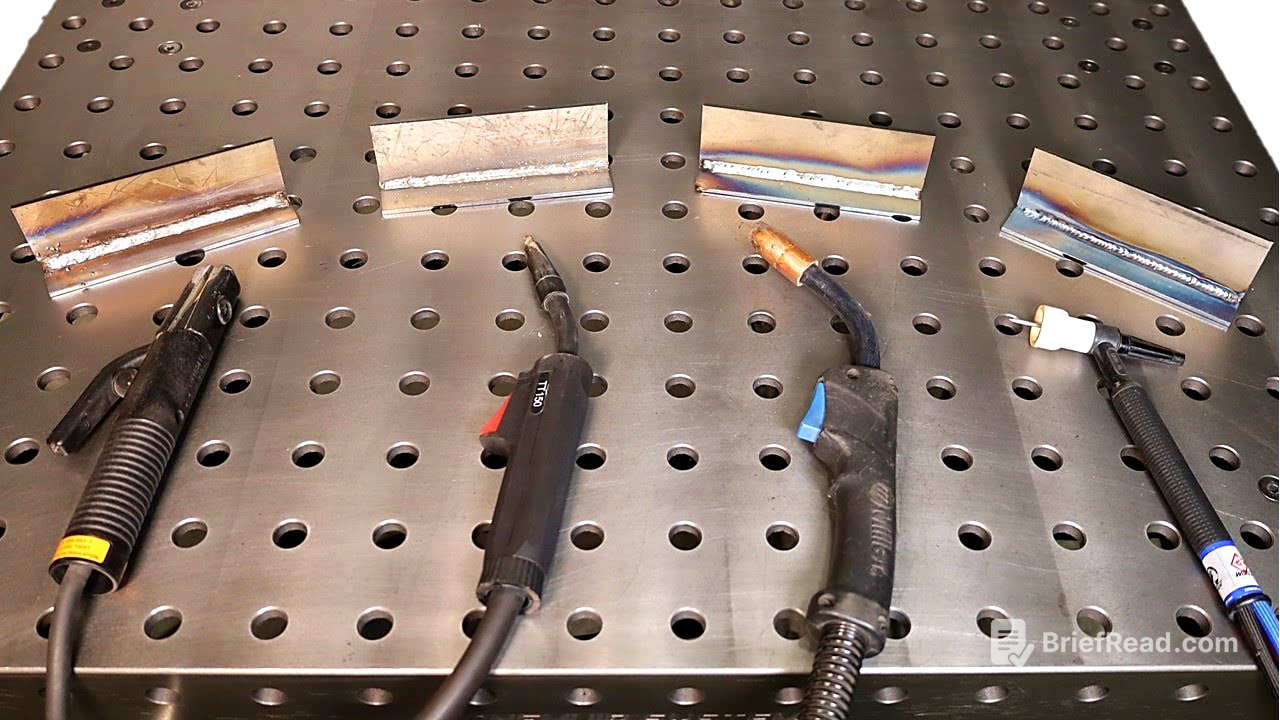

Stick welding, also known as shielded metal arc welding (SMAW), uses consumable stick electrodes to create a weld. The electrode consists of a metal rod, similar to the base metal being welded, surrounded by a flux coating. An electrical clamp (electrode holder) is connected to the rod, allowing electricity to flow from the welder through the rod. Touching the rod to the workpiece creates a short circuit, initiating an arc that generates intense heat, melting both the base metal and the electrode. The molten metal from the rod is deposited into the weld. The flux coating burns off during the process, shielding the molten metal from atmospheric contamination. As the rod burns down, the welder moves their hand closer to maintain a consistent arc. After welding, a slag coating remains, which is removed using a chipping hammer to reveal the finished weld. Stick welding is inexpensive and portable, making it suitable for general-purpose work, repairs, structural applications, furniture, and trailer fabrication. However, it is not ideal for thin sheet metal due to the risk of burn-through, and the slag coating requires additional cleanup.

Flux Core Arc Welding - FCAW [4:00]

Flux core arc welding (FCAW) is similar to stick welding but uses a continuously fed tubular wire filled with flux. Instead of manually feeding a stick, a motor feeds the flux-cored wire through a gun. This process is easier to learn than stick welding because it eliminates the need to strike an arc manually and maintain a consistent arc length. The equipment can be relatively inexpensive, with basic flux core welders available for under £200. FCAW can be used on various material thicknesses, from thin sheet metal to thicker industrial applications. Like stick welding, FCAW produces a slag coating that needs to be removed after welding. The user maintains a steady distance between the gun and the workpiece while welding.

MIG Welding (Gas Metal Arc Welding - GMAW) [5:58]

MIG (Metal Inert Gas) welding, also known as gas metal arc welding (GMAW), is a process that uses a continuously fed wire electrode and a shielding gas to protect the weld pool. The wire, typically steel coated in copper, is fed through a gun, and a shielding gas (such as carbon dioxide, argon, or a mixture) is supplied through a nozzle around the wire. The shielding gas prevents atmospheric contamination, eliminating the formation of slag. MIG welding is fast and clean, making it suitable for thin sheet metal, auto body work, and various other applications. The presenter's machines can weld up to 3/8 inch thick material in a single pass. However, MIG welding equipment is more expensive than flux core or stick welding due to the cost of the machine and the required gas cylinder. It is also less portable because of the need to transport the gas cylinder. It is possible to start with a MIG machine and use flux core wire before adding the gas cylinder later.

TIG Welding (Gas Tungsten Arc Welding - GTAW) [7:45]

TIG (Tungsten Inert Gas) welding, also known as gas tungsten arc welding (GTAW), uses a non-consumable tungsten electrode to create an arc and a separate filler rod to add metal to the weld pool. A shielding gas is used to protect the weld area from contamination. TIG welding offers the most control and precision, making it ideal for precise work and fine control. To add filler metal, an additional rod is fed into the weld pool. TIG welding is particularly well-suited for welding aluminium, but this requires a machine that can output alternating current (AC) as well as direct current (DC), which increases the cost. TIG welding machines are in a similar price range to MIG welding machines, with AC options being more expensive. Most TIG welding machines can also be used for stick welding. Multi-process machines that combine MIG, TIG, and stick welding capabilities are available, but their TIG function may be more limited, often using a lift arc for starting and typically only outputting direct current (DC) for TIG, which limits their ability to weld aluminium. When using multi-process machines, it's important to note that MIG and TIG welding may require different types of shielding gas, necessitating the purchase of two gas cylinders.

![AI in HR: What You Need to Know [2025]](https://wm-img.halpindev.com/p-briefread_c-10_b-10/urlb/aHR0cDovL2ltZy55b3V0dWJlLmNvbS92aS96c0hYSzFZNTd5RS9ocWRlZmF1bHQuanBn.jpg)